In today’s fast-paced manufacturing industry, businesses are constantly looking for efficient, precise, and cost-effective ways to produce plastic components. One of the most widely adopted methods is custom injection molding. This process has become the backbone of industries ranging from automotive and electronics to medical devices and consumer goods. But what exactly is custom injection molding, and why is it so important for modern manufacturing?

Understanding Custom Injection Molding

Custom injection molding is a specialized manufacturing process used to create plastic components tailored to a company’s specific requirements. Unlike standard injection molding, where molds are pre-designed for mass production, custom injection molding focuses on creating molds and parts that are unique in design, size, and function.

The process begins with designing a mold based on the client’s specifications. This mold is then used to inject molten plastic into the cavity under high pressure. Once cooled, the plastic solidifies into the desired shape. What makes it “custom” is that every aspect — from the mold design to the choice of plastic material — is optimized for the client’s product needs.

Why Businesses Choose Custom Injection Molding

Design Flexibility

Custom injection molding allows manufacturers to create complex shapes, intricate details, and precise dimensions. This flexibility ensures that even the most challenging product designs can be turned into reality.Material Variety

Depending on the product’s application, businesses can choose from a wide range of plastics, including ABS, polypropylene, nylon, and polycarbonate. Each material offers different benefits such as strength, durability, or chemical resistance.Cost Efficiency for Large Volumes

While the initial mold creation requires investment, the process becomes highly cost-effective for high-volume production runs. Each cycle produces consistent parts, reducing waste and errors.Consistency and Precision

Custom injection molding ensures uniformity in every batch of components. Whether you need 1,000 parts or 1,000,000, the quality and specifications remain consistent.Scalability

Once the custom mold is ready, scaling up production is easy, making it an ideal choice for industries with growing demands.

Applications of Custom Injection Molding

Custom injection molding is widely used across industries:

- Automotive: For dashboards, bumpers, and under-the-hood components.

- Medical: To create syringes, housings for medical devices, and safety equipment.

- Consumer Goods: From packaging to toys and household items.

- Electronics: For casings, connectors, and precision parts.

- Industrial Applications: Components for machines, tools, and equipment.

In each of these industries, the ability to produce high-quality, custom-fit components makes injection molding an irreplaceable solution.

The Process at a Glance

Design & Prototyping – The client’s requirements are studied, and a mold design is created.

Mold Fabrication – High-precision molds are manufactured using advanced tools.

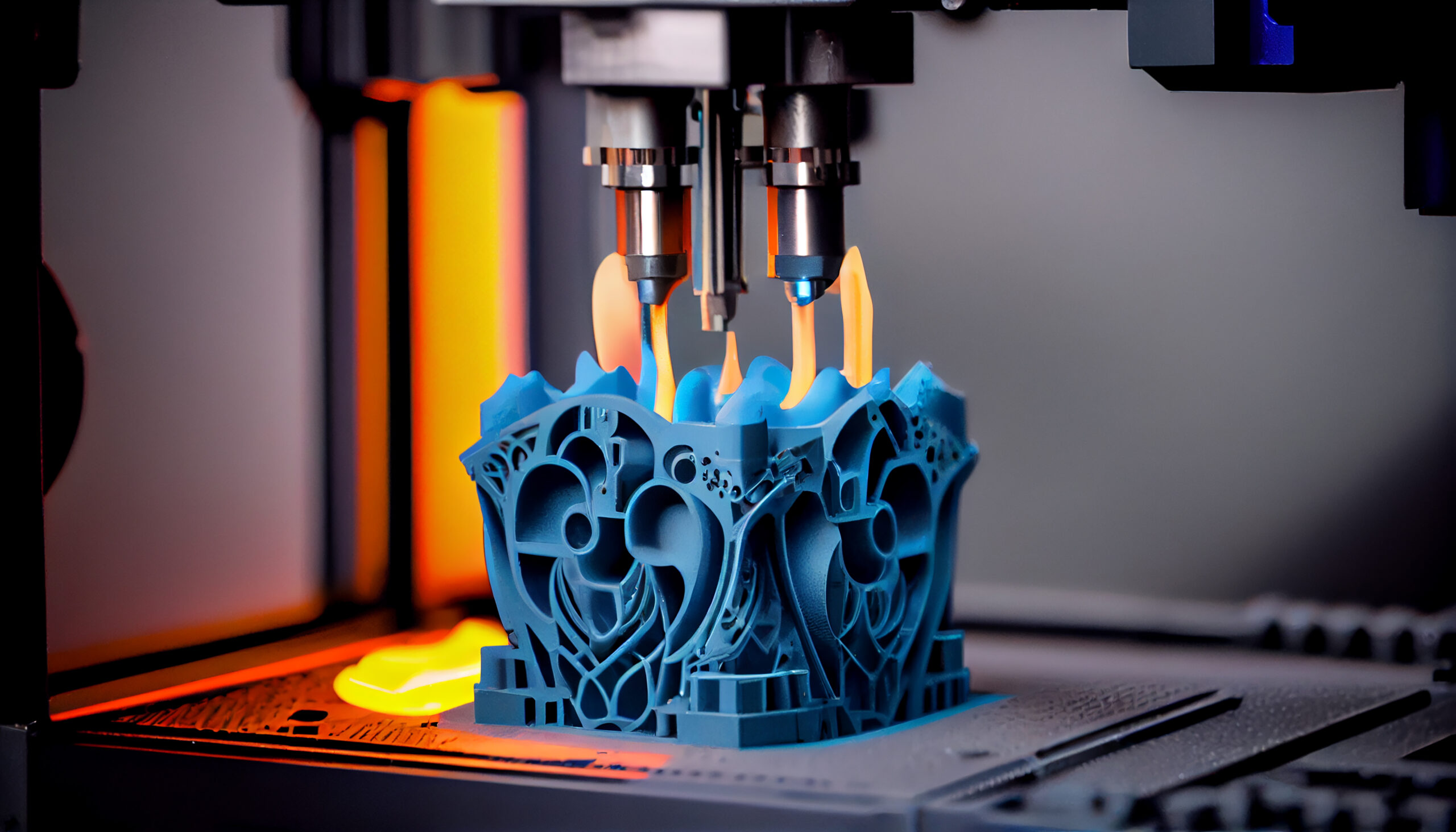

Injection Molding – Molten plastic is injected under pressure into the mold cavity.

Cooling & Ejection – The part is cooled and ejected from the mold.

Quality Inspection – Every component is checked for defects and accuracy.

Why Partner with Northern Plastics Engg?

At Northern Plastics Engg, we specialize in providing custom injection molding solutions for businesses across India, USA, UAE, Canada, Turkey, France, Italy, Saudi Arabia, Germany. With years of expertise, state-of-the-art machinery, and a team of skilled engineers, we ensure every project meets the highest standards of precision, durability, and efficiency.

Whether you are a startup looking for prototype development or an established business needing large-scale production, Northern Plastics Engg can deliver reliable, tailor-made injection molding services in India, USA, UAE, Canada, Turkey, France, Italy, Saudi Arabia, Germany that align perfectly with your needs.