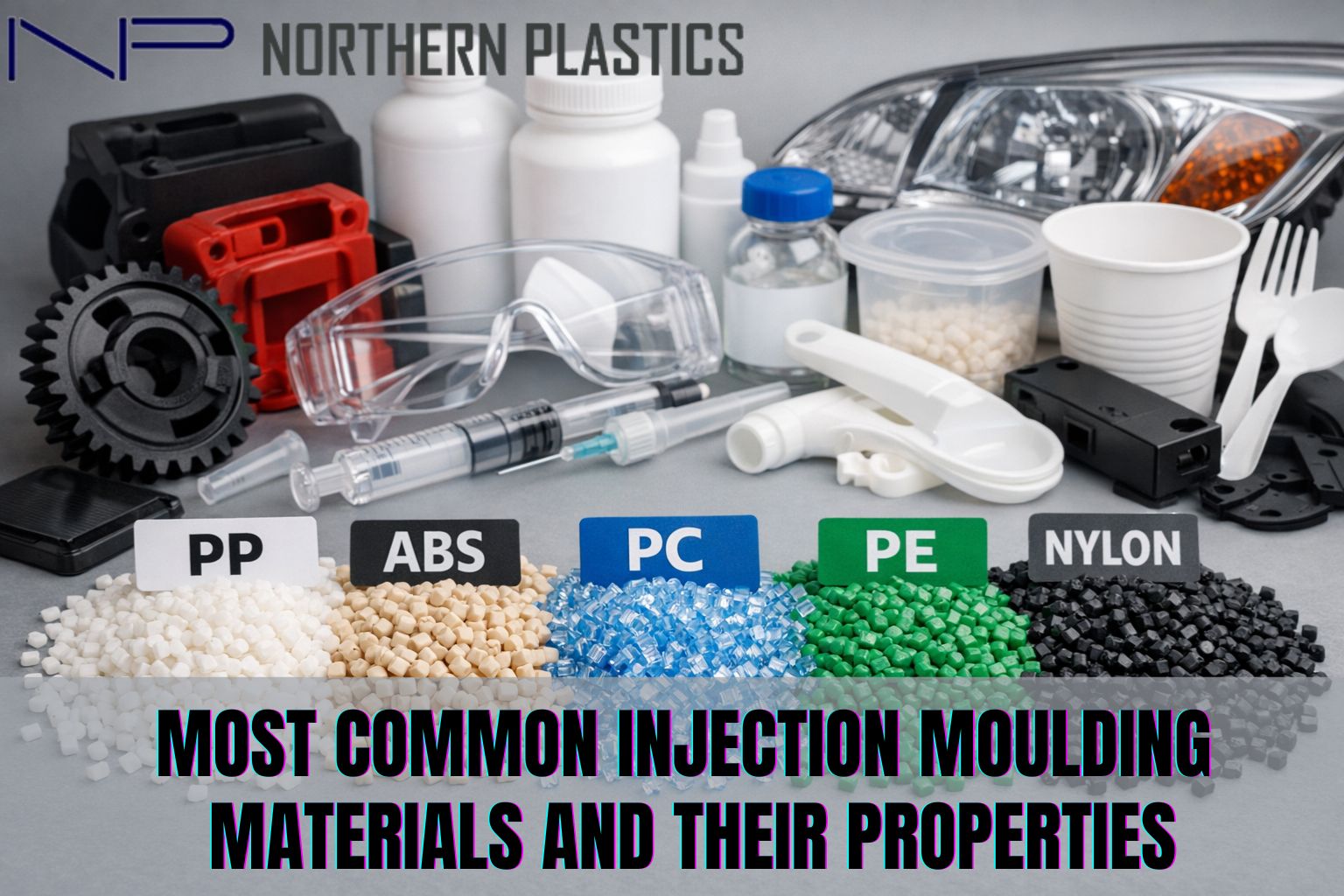

Injection moulding is super important in today’s manufacturing world it allows for the mass production of accurate, strong and affordable plastic parts. The quality and effectiveness of any injection molded item mainly rely on the type of material used. The various sectors like automotive, electronics, healthcare and packaging which needs plastic that have particular mechanical, thermal and chemical characteristics. Northern Plastic Engineering is known the most frequent injection moulding and their trait assists manufacturer in selecting the appropriate resin for durable and high performing products.

Polypropylene

Polypropylene is a popular thermoplastic that is well known for its effectiveness and cost effectiveness in injection moulding. It features great fatigue resistance, outstanding chemical and moisture resistance which makes it lightweight with decent flexibility. You can find it in automotive trim parts, medical disposables, packaging containers, living hinges and various customer products that makes it perfect for situations that need repeated bending and resistance to chemicals.

Acrylonitrile Butadiene Styrene (ABS)

ABS is a type of engineering plastic that is known for its high impact resistance, solid dimensional stability and ease of processing and coloring. It is tough rigid and provides a great surface finish. You will often find it used in common applications like housing, car interiors, electronic enclosures, toys and office gears which makes it a reliable option when you need both durability and looks.

Polycarbonate

Polycarbonate is a high quality injection moulding material recognized for its incredible impact strength, great heat resistance, high transparency and decent flame resistance. The common use ranges from electrical component to automotive lighting, medical devices, safety gears and optical parts by making it a perfect for scenarios that need a mix of strength, clarity and heat resistance.

Polyethylene

It comes in different grade like LDPE and HDPE that makes it a flexible material for injection moulding. It is known for its toughness, great chemical resistance, low moisture absorption and lightweight flexibility. You will usually find it in caps, closures, containers, household items, industrial components and packaging solution especially in settings where moisture and chemicals are present.

Polystyrene

Polystyrene is a tough and budget friendly plastic that is often used in molding for lightweight items. It has a nice surface finish as it is rigid, inexpensive and easy to mold. You will typically find it in food packaging, disposable utensils, cosmetic containers and lab products. However it is not suitable for applications that requires high impact and strength.

Nylon

It is a strong engineered plastic recognized for its significant tensile strength, outstanding wear and abrasion resistance, commendable thermal stability and minimal friction. It is frequently used in high performance injection molding applications, especially in automotive engine components, gears, bearing, industrial housing and mechanical parts by making it suitable for parts under mechanical stress and high temperature.

Importance of Material Selection in Injection Molding:

Selecting the right injection molding material has a direct effect on the strength, durability, cost and performance of the product. It is important to take into account factors like operating temperature, load condition, environmental exposures and regulatory requirements. At Northern Plastic Engineering our skilled team focuses on material selection to ensure that injection molded parts meet the industry standards that meets the functional needs and satisfies the customer expectations.

Conclusion:

The material used in injection molding comes in a variety of properties which makes choosing the right one a key part of developing a product. Whether it is budget friendly but each material has its own specific use. By getting to know these materials and collaborating with a skilled injection molded manufacturer like Northern Plastic Engineering will ensure high quality, efficiency and dependability in their plastic parts.