Plastic injection molding is one of the most widely used manufacturing processes in the modern industrial world. From everyday household products to high-performance automotive parts, this technology is at the core of mass-producing precision plastic components. But what exactly is plastic injection molding, and how does it work?

In this blog, we’ll break down the basics of the plastic injection molding process, its advantages, and how manufacturers like Northern Plastics Engg in India are using this method to deliver consistent, high-quality plastic products across industries.

What is Plastic Injection Molding?

Plastic injection molding is a manufacturing process used to create plastic parts by injecting molten plastic material into a mold cavity, where it cools and solidifies into the final shape. The molds are usually made of metal (steel or aluminum) and are designed to withstand high temperatures and pressures.

This method is highly effective for mass-producing identical plastic parts with high precision, making it ideal for industries such as:

- Automotive

- Consumer electronics

- Medical devices

- Packaging

- Household goods

- Industrial machinery

How Does Plastic Injection Molding Work?

The process of plastic injection molding involves several key steps:

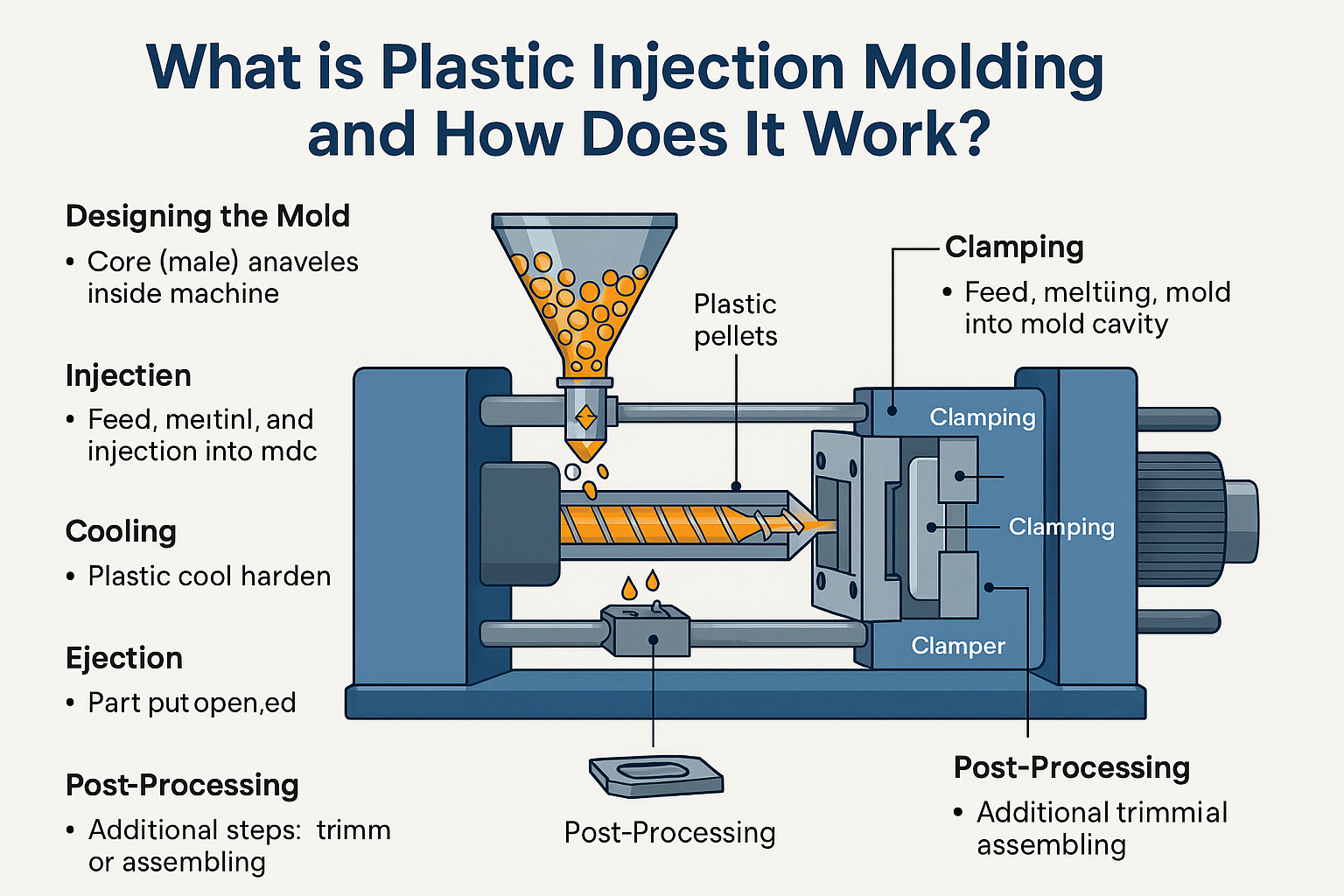

- Designing the Mold

The first step is designing a mold based on the part’s specifications. This mold typically consists of two halves:

- Core (male) and

- Cavity (female)

These two halves are machined to form the negative image of the product.

- Clamping

Once the mold is prepared, it is mounted inside an injection molding machine. The two halves of the mold are clamped together tightly using hydraulic or mechanical force to withstand the pressure of the injection process.

- Injection

Plastic pellets (usually thermoplastic materials) are fed into the machine’s hopper. These pellets are then heated and melted in the barrel. Once the plastic reaches the desired temperature, it is injected under high pressure into the mold cavity.

- Cooling

As the molten plastic fills the mold, it begins to cool and harden. Cooling time depends on the type of plastic and the thickness of the part. This is one of the most critical phases to ensure proper shape and structural integrity.

- Ejection

Once the plastic part has cooled and solidified, the mold opens, and ejector pins push the part out of the mold. The mold then closes again to repeat the cycle.

- Post-Processing

The finished parts may require trimming, polishing, or assembly before packaging and delivery. Sometimes, additional quality checks are conducted to ensure dimensional accuracy.

Why Choose Plastic Injection Molding?

Plastic injection molding offers numerous advantages:

✅ High Precision

This method allows for producing parts with tight tolerances and consistent quality.

✅ High Efficiency

Once the mold is ready, thousands of parts can be produced rapidly with minimal labor input.

✅ Low Waste

Most plastic scrap can be recycled and reused, making it an eco-friendly option compared to other methods.

✅ Scalability

It is highly suitable for large-volume production and repetitive manufacturing.

✅ Wide Material Selection

From flexible rubber-like plastics to strong engineering-grade materials, manufacturers can choose materials suited to the application.

Applications of Injection Molding in India

In a rapidly growing manufacturing economy like India, USA, UAE, Canada, Turkey, France, Italy, Saudi Arabia, Germany, plastic injection molding plays a vital role. Industries such as automobile production, FMCG packaging, electronics manufacturing, and agricultural equipment heavily rely on this technique.

With the Make in India initiative and a growing emphasis on local production, demand for reliable plastic component manufacturers is on the rise — and that’s where Northern Plastics Engg comes in.

Why Choose Northern Plastics Engg?

At Northern Plastics Engg, we specialize in custom plastic injection molding solutions that meet the exact requirements of your application. Here’s what sets us apart:

- State-of-the-art molding machines

- Experienced mold designers and toolmakers

- Quick turnaround times

- In-house mold base and die manufacturing

- Cost-effective production with zero compromise on quality

Whether you need small, intricate components or large-scale molded parts, we can help you bring your designs to life.

Final Thoughts

Plastic injection molding is a cost-effective, efficient, and scalable method to produce high-quality plastic parts across multiple industries. With the right partner, such as Northern Plastics Engg, businesses in India, USA, UAE, Canada, Turkey, France, Italy, Saudi Arabia, Germany can gain access to world-class molding services that deliver both value and performance.

Whether you’re a startup looking to prototype your first product or a manufacturer in need of bulk production, plastic injection molding is a smart choice.