In today’s competitive world of manufacturing maintain accuracy, strength and efficiency is important. Metal Injection Molding by Northern Plastics has emerged as a new technology that merges the flexibility of plastic injection molding with durability of metal. This advance process enables manufacturers to make complex, high performance metal parts with outstanding accuracy and minimum waste that truly transform industries from automotive to medical aerospace.

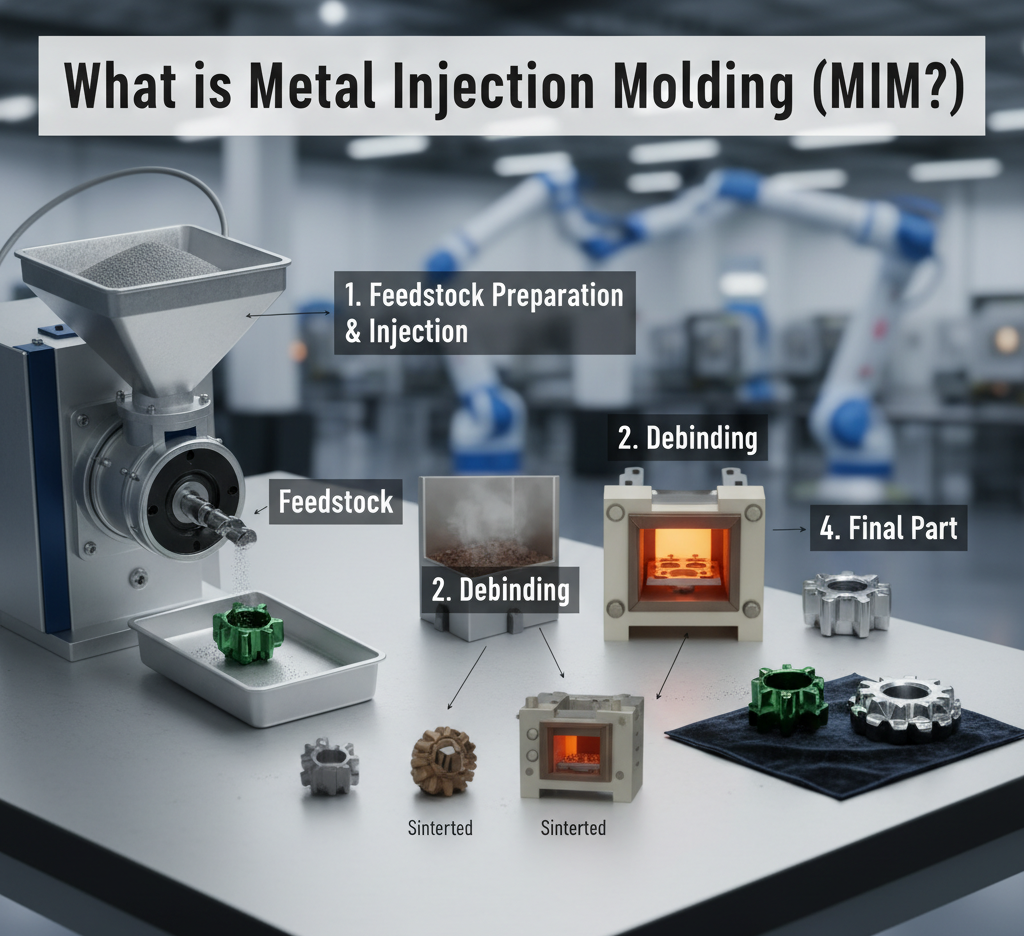

What is Metal Injection Molding (MIM)?

Metal Injection Molding is an innovative manufacturing technique designed for producing small and detailed metal component in large volume. It starts with a mixture of fine metal powders combined with thermoplastic binder to create a feedstock. This feedstock is injected into a mold cavity that is similar to plastic injection molding. After shaping the binder is carefully removed and the component undergoes the high temperature sintering process.

Characteristics of Metal Injection Molding:

- Tight Tolerance: It ensures precise dimensions and reliable outcome throughout mass production.

- Part Merging: It allows for merging several components into one part which helps in reducing assembly line.

- High Material Utilization: Minimum material waste due to the high accuracy of the process and high recyclability.

Advantages of Metal Injection Molding:

- Complex Shapes: Metal Injection Moulding MIM in France enables the creation of complex design that hard or even impossible to achieve with the use of traditional machinery or casting method.

- Strength & Accuracy: The solid component offers tight tolerance and excellent mechanical properties.

- Large Scale Production: These are perfect for manufacturing high volumes of precision parts at affordable price of CNC machines.

- Material Variety: MIM caters a wide range of metals such as stainless steel, titanium and copper alloys.

Applications of Metal Injection Molding:

MIM Metal Injection Moulding in France is becoming popular rapidly in different industries. As French manufacturers is adopting MIM due to its ability to provide precision, performance and sustainability at one process.

- Automobile industries: They uses it for gears, turbocharger components and locking mechanism.

- Medical Producers: They depend on MIM for surgical instruments and orthodontic brackets.

- Aerospace Industry: Metal Injection Molding is valued for its light weight and high strength parts.

Final Thoughts:

Metal Injection Moulding is leading a way in today’s metal manufacturing technique. We at Northern Plastics merges the design of plastic with the strength of metals, providing a cost effective and ecofriendly way to make complex design in large quantities. For MIM Metal Injection Moulding in France look for advance manufacturing option that is essential for driving innovation, boosting efficiency and quality in every piece.

Frequently Asked Question:

- What kind of materials is used in MIM process?

A variety of metals can be used in MIM process such as stainless steel, titanium and copper alloys.

- Which industries are commonly part of metal injection molding?

Metal injection molding is widely used in automotive, aerospace, electronics and medical industries for producing durable, light weight and accurate components.

- What are the main benefits of MIM Metal Injection Moulding in France?

MIM offers design flexibility, high material utilization, reduced assembly needs and ability to manufacture complex shape in low cost.

- Do MIM components are accurate?

Yes, as they ensures tight tolerance and accurate dimension compared to CNC machines.