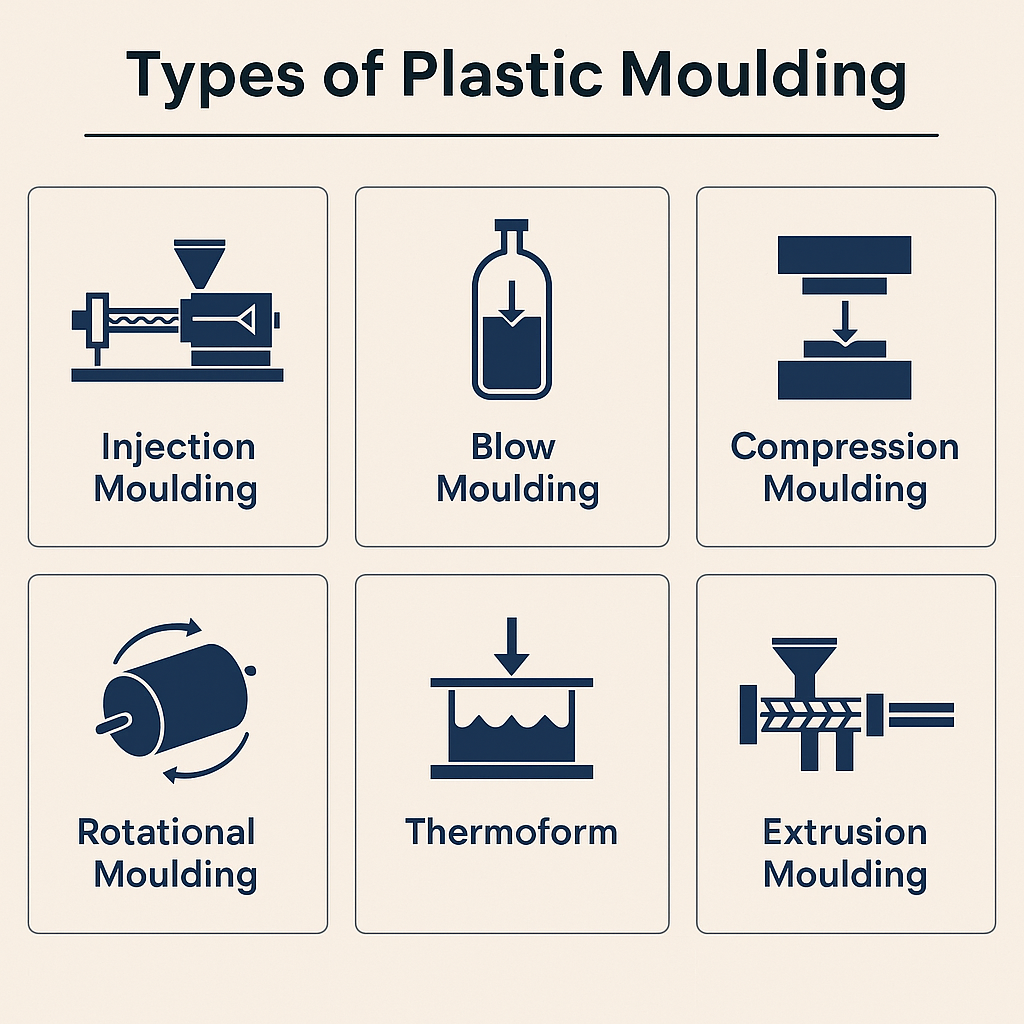

In the world of modern manufacturing, plastic moulding has become a cornerstone for producing durable, high-precision, and cost-effective components across industries — from automotive and electrical to consumer goods and healthcare. But did you know that there are multiple types of plastic moulding techniques, each suited for different applications?

If you’re a product developer, engineer, or manufacturer looking to understand the right plastic moulding process for your requirements, this blog is for you.

Let’s explore the major types of plastic moulding used in the industry today.

- Injection Moulding

Injection moulding is by far the most widely used plastic moulding process across industries. In this method, melted plastic is injected into a custom-made mould under high pressure. Once the plastic cools and solidifies, the finished product is ejected.

Key Applications:

- Automotive parts

- Consumer electronics

- Medical devices

- Industrial components

Advantages:

- High production speed

- Excellent dimensional accuracy

- Supports complex geometries

- Ideal for large-scale production

At Northern Plastics Engg, we specialize in precision injection moulding, ensuring consistency and quality in every part we deliver.

- Blow Moulding

Blow moulding is commonly used for making hollow plastic products. It involves heating plastic and inflating it into a mould cavity, similar to blowing up a balloon.

Key Applications:

- Bottles (for water, oil, shampoo, etc.)

- Containers

- Plastic drums

Types:

- Extrusion Blow Moulding

- Injection Blow Moulding

- Stretch Blow Moulding

Blow moulding is particularly advantageous when producing lightweight and uniform hollow parts at high volumes.

- Compression Moulding

This process involves placing a pre-heated plastic material into a heated mould cavity. The mould is then closed with pressure to shape the plastic. It is best suited for thermosetting plastics.

Key Applications:

- Automotive panels

- Electrical housings

- Large-scale parts

Advantages:

- Lower tooling costs

- Good for low to medium production volumes

- Suitable for large, high-strength parts

At Northern Plastics Engg, we can consult you on whether compression moulding suits your product, especially for low-run or cost-sensitive projects.

- Rotational Moulding (Rotomoulding)

In rotational moulding, plastic powder is placed into a hollow mould which is then rotated in an oven, allowing the plastic to coat the interior evenly.

Key Applications:

- Water tanks

- Playground equipment

- Storage containers

Advantages:

- Uniform wall thickness

- Minimal material waste

- Suitable for very large hollow objects

While it has slower cycle times, rotomoulding offers design freedom and low-cost tooling for larger items.

- Thermoforming

Thermoforming involves heating a plastic sheet until it becomes pliable, then forming it over a mould using vacuum or pressure.

Key Applications:

- Packaging trays

- Disposable cups and containers

- Automotive interior panels

Types:

- Vacuum Forming

- Pressure Forming

- Twin Sheet Forming

Thermoforming is ideal for lightweight packaging and prototypes.

- Extrusion Moulding

Extrusion moulding is used to create continuous profiles like tubes, pipes, and sheets. Plastic is melted and forced through a die, shaping it as it cools.

Key Applications:

- Plastic pipes

- Window frames

- Sealing strips

Advantages:

- Continuous, high-volume production

- Cost-effective for long parts

- Suitable for simple cross-sections

How to Choose the Right Plastic Moulding Process?

Choosing the right moulding method depends on several factors:

- Product size and shape

- Volume of production

- Material type

- Tolerance and finish requirements

- Budget and tooling investment

Working with an experienced moulding partner like Northern Plastics Engg ensures that you select the most effective process that balances quality, efficiency, and cost.

Why Choose Northern Plastics Engg?

At Northern Plastics Engg, we bring over two decades of experience in delivering top-quality plastic injection moulds, dies, and mould bases. We cater to diverse industries and provide end-to-end support — from design consultation and prototyping to tooling and final production.

✅ What We Offer:

- High-precision injection moulding

- Custom mould base and die manufacturing

- Rapid prototyping support

- Durable and consistent plastic parts for industrial use

Whether you are a startup launching a new product or an established OEM scaling production, we offer cost-effective and reliable plastic moulding solutions right here in India, USA, UAE, Canada, Turkey, France, Italy, Saudi Arabia, Germany.