In modern competitive manufacturing scene, Custom Injection Molding plays an important role in creating high quality plastics that are accurate, reliable and consistent. Whether it is for automotive, medical industry, consumer goods and industrial component, this process guarantees that each product adheres to specific design requirement. At Northern Plastics we specialize in Plastics Injection Molding Services which provides innovative, durable and cost effective solution for any business size.

What is Custom Injection Molding?

Custom Injection Molding is a process used in manufacturing that creates a plastic parts by injecting melted material in customized mould. Each mold is crafted to meet the exact need of a product including its shape, size and function. This technique allows manufacturer to create accurate and complex mold designs with outstanding consistency.

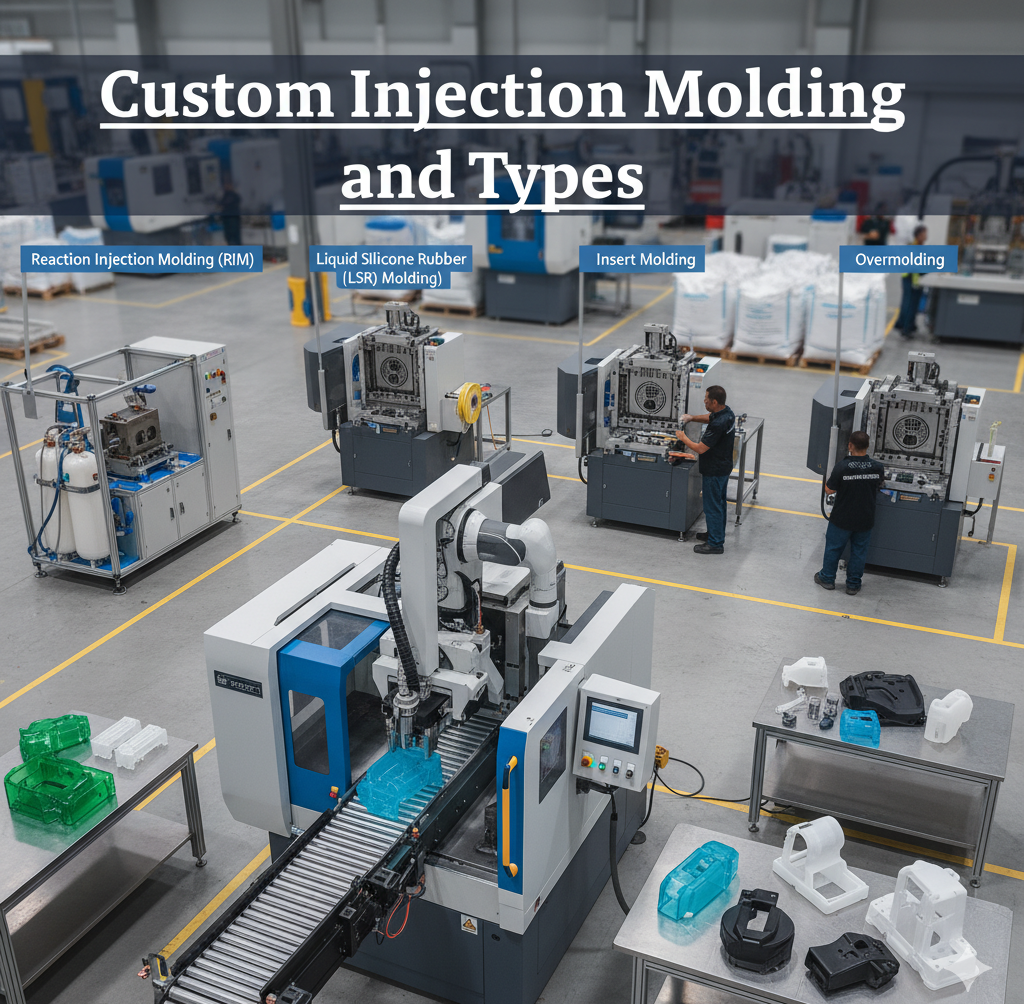

Types of Custom Injection Molding:

- Thermoplastic Injection Molding:

It is a manufacturing process where you heat up the thermoplastic material until it melts, then inject it under a high pressure into a mold to form a final product. This process involves heating plastic pellets in a barrel, melting them with a rotating screw and pushing the liquid plastic into a molded shape like a final part, where it cool downs and harden.

- Over Molding:

It is a manufacturing technique that involves molding a second material over an existing part, it is also known as substrate, to form a unified content. This method creates a permanent bond between various material like rigid plastic substrate and a flexible rubbery over mold, which results that a product is not only durable but also offers improved grip and feel.

- Insert Molding:

Insert Molding is a type of Plastic Injection Molding Services where pre made pieces are known as insert, is placed into a mold before hot plastic is injected around it forming a single part. This method merges material such as metal and plastic to boost strength or add features like threads, which eliminates the need of separate assembly steps and helps in reducing cost.

- Micro Injection Molding:

It is a high accuracy manufacturing technique which is used to make tiny plastics, that usually weights in gram, with complex detail and strict tolerance. It uses specialized machines and smaller molds to create components for medicines, electronic parts and other devices, which benefits in high accuracy, efficient use of material and fast production cycle for small units.

- Gas Assisted Injection Molding:

It is a molding technique that uses compressed gas to create a hollow interior into a thick plastic component which results in light weight structure. This method reduces material use and weight, while the gas pressure helps to remove sink marks. It enhances dimensional stability and surface quality.

Why to Choose Northern Plastic Engineering?

We at Northern Plastics takes a pride to be a reliable Injection Molding Companies in a molding industry. Our skilled team is combined of technical experts with advance equipments to provide fully tailored Custom Injection Molding solution. From prototype development to full scale production, we focus on accuracy, innovation and reliability. Our dedication towards quality guarantees a long term partnership regardless of the product complexity & sizes.

Conclusion:

Custom Injection Molding is the backbone of today’s manufacturing, providing flexibility, cost effectiveness and exceptional accuracy. Whether you are looking for a small batch production or large scale production, Northern Plastics offers premium Plastics Injection Molding Services that fits your need. Partner with us to enjoy world class engineering, advance technology and reliable business needs.

Frequently Asked Question:

- What materials are used in custom injection molding?

The common materials are used in injection molding are thermoplastics, thermosetting polymers and elastomers.

- How is insert molding different from regular molding?

Insert molding uses pre made components into the mold before injecting plastics to from a single part.

- What are the benefits of gas injection molding?

It is used in creating lightweight, hollow part with smooth surface and improved structural strength while reducing material cost.

- Why is Over molding is used?

It is used to combine two material, improving product grip, durability and aesthetics.